01.29.25

The Best ERP Systems for Manufacturing: Optimize Production & Supply Chains">

The Best ERP Systems for Manufacturing: Optimize Production & Supply Chains">

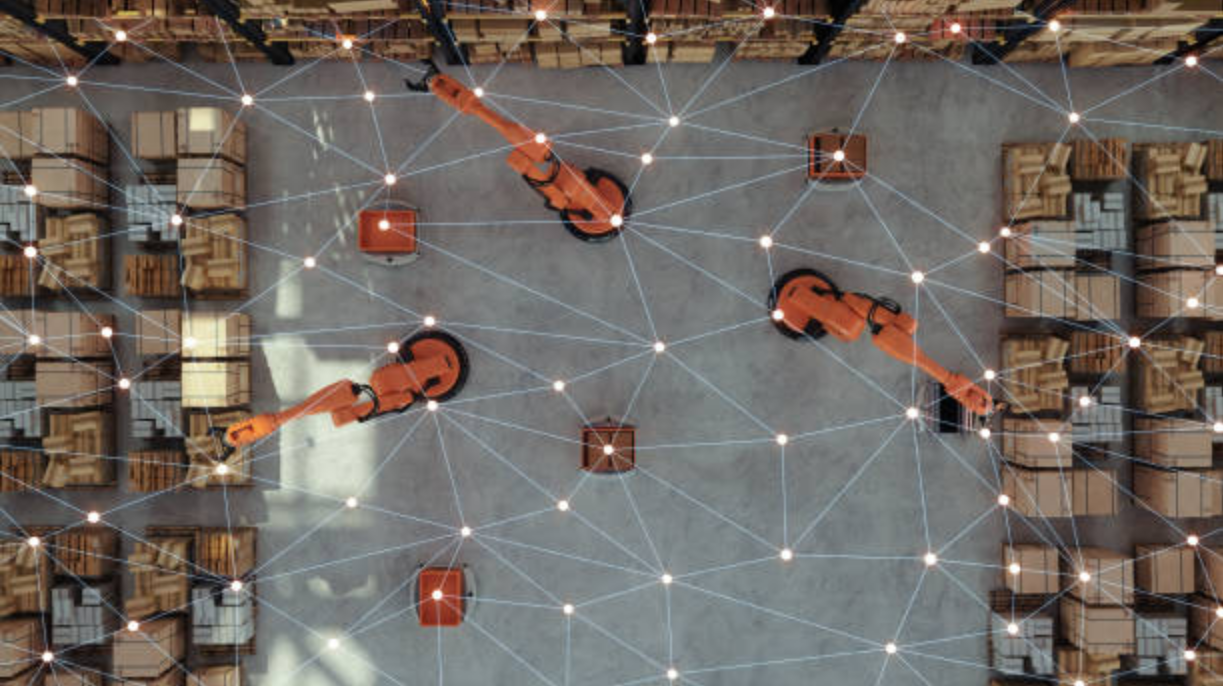

Manufacturers today face unprecedented challenges. Global supply chain disruptions, fluctuating material costs, and the increasing demand for faster production cycles mean businesses must operate at peak efficiency. Traditional ERP solutions often fall short because they aren’t designed with modern manufacturing complexities in mind.

That’s why choosing the right ERP system for manufacturing is more than just selecting software—it’s about future-proofing operations. The best manufacturing ERP software doesn’t just track inventory and finances; it orchestrates production schedules, minimizes waste, and improves profitability in real time.

But with so many ERP systems for manufacturing on the market, which one is the right fit? Let’s break it down.

When evaluating manufacturing ERP systems, companies should focus on five critical areas:

Production Planning & Scheduling – Can the system efficiently allocate resources, manage lead times, and optimize machine usage?

Supply Chain & Inventory Management – Does it offer real-time tracking, procurement automation, and vendor management?

Financial Management & Cost Control – How well does the ERP track production costs, profits, and budgets?

Regulatory Compliance & Quality Control – Does it ensure industry standards and regulatory adherence?

Scalability & Cloud Integration – Can the system grow with the business and support remote or multi-site operations?

Now, let’s compare two leading manufacturing ERP solutions that check all these boxes.

If you’re a small to mid-sized manufacturer looking for an ERP that scales with your business, Acumatica Manufacturing Edition is a cloud-based powerhouse. It allows manufacturers to streamline production, inventory, and financial management without heavy upfront costs. Acumatica’s flexibility and real-time analytics make it an excellent choice for companies looking to modernize operations without a complex, expensive implementation process.

Best for: Manufacturers seeking an affordable, scalable cloud-based ERP.

Why it stands out: Real-time data access, flexible deployment, and seamless third-party integrations.

For large manufacturers dealing with complex supply chains and global operations, Microsoft Dynamics 365 Supply Chain Management delivers an AI-powered ERP platform. Its machine-learning-based demand forecasting, IoT-enabled predictive maintenance, and deep analytics make it a robust choice for enterprise-level manufacturing. If your company requires a highly customizable solution with advanced automation, Dynamics 365 is the way to go.

Best for: Large-scale manufacturing enterprises with complex production and supply chain demands.

Why it stands out: AI-powered demand forecasting, predictive analytics, and deep integration with Microsoft products.

For growing manufacturers looking for a cost-effective, cloud-based solution, Acumatica is a strong choice. Its scalable design allows businesses to expand without heavy upfront costs, making it ideal for small to mid-sized manufacturers that need flexibility and real-time data access.

For large enterprises that require advanced automation and deep analytics, Microsoft Dynamics 365 stands out. Its AI-driven demand forecasting, predictive analytics, and supply chain management tools make it an excellent fit for manufacturers managing complex production workflows and large-scale operations.

Both Acumatica and Microsoft Dynamics 365 provide powerful ERP solutions that integrate real-time data insights, financial tracking, and inventory management. By choosing the right ERP system, manufacturers can make more informed decisions, improve operational efficiency, and optimize production processes to remain competitive in a rapidly evolving industry.

Selecting the best ERP system for manufacturing isn’t just about software—it’s about how well it integrates into your business processes. Clients First Business Solutions has helped manufacturers implement customized ERP solutions that streamline operations, reduce costs, and boost overall productivity.

Not sure which manufacturing ERP system fits your needs? Let’s talk! Our team specializes in end-to-end ERP implementation, customization, and ongoing support to ensure seamless adoption and maximum ROI.

Contact Clients First Business Solutions today to discuss your ERP needs and take the next step toward a more efficient manufacturing future.

Our team brings unmatched efficiency and value for a smooth implementation and beyond. Find out how we can help your business gain a competitive advantage in the marketplace.

Free Consultation