With an enterprise cost accounting software solution, your organization can track, record and analyze costs associated with different activities in your organization. A fully integrated cost accounting enterprise system outweighs the inconvenience of utilizing a grandfathered system that does not interconnect accounting with other business areas; including resource management, project execution, supply chain, marketing and sales. A complete enterprise wide software integration is today's key to obtaining real-time insight into you business and obtaining organizational goals.

With an enterprise cost accounting software solution, your organization can track, record and analyze costs associated with different activities in your organization. A fully integrated cost accounting enterprise system outweighs the inconvenience of utilizing a grandfathered system that does not interconnect accounting with other business areas; including resource management, project execution, supply chain, marketing and sales. A complete enterprise wide software integration is today's key to obtaining real-time insight into you business and obtaining organizational goals.

Cost Accounting Functionality in ERP Software Solutions

Most ERP systems, including Dynamics AX 2012, incorporate special tools that end-users can use to manage the following:

- Fixed, variable, average and marginal costs relating to manufacturing/non-manufacturing activities

- Build multi-level cost categories

- Allocate costs based on quantity, number of hours, square footage and so on

- Develop forecasts and budgets

- Predict the impact of different business decisions on costs and bottom line, implicitly

- Perform cost flow analyses to measure variances against actual costs.

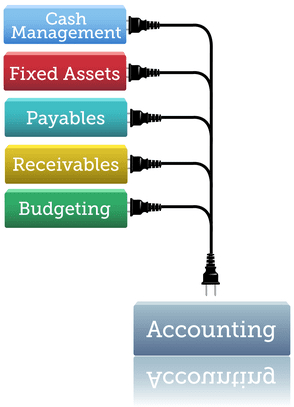

To suit individual business needs, software that facilitates cost accounting functionality, such as Enterprise Resource Planning (ERP), allow users to configure procurement, production, inventory management, accounts payable, accounts receivable, master planning and other parameters that affect cost management. Various parameter settings deliver complex cost management scenarios, which function based on:

- Standard Costing: Standard costing includes the cost of direct materials, direct labor and manufacturing overhead (expenses associated with the manufacturing process). If a variance between the standard and actual cost arises, you can use different tools to analyze that variance and understand how the standard cost differs from the actual cost. If the actual cost is greater than the standard cost, the variance is unfavorable, which means that the profit will be less than planned. Conversely, if the actual cost is less than the standard cost, the variance is favorable, which means that the profit margin will exceed the planned level. A great example of this is the ability to report Material Quantity Variances in Dynamics AX 2012.

- Absorption Costing: Cost accounting software puts at your disposal the tools needed to calculate absorption costing, which includes overhead expenses along with the total direct cost. Absorption costing is very important in external reporting.

- Line Structures and Hierarchies: Part of cost accounting modules, line structures are used together with hierarchies to group cost dimensions, classify costs and develop expense distribution sheets, which are critical to create profit center structures. Based on hierarchies, users can execute various financial reports.

- Expense Distribution Sheets: With the help of expense distribution sheets, you can analyze different cost dimensions, create reports for one or more divisions and compare actual with budget costs. Period calculation, special calculation and plan calculation are three types of cost balances to be considered when creating expense distribution sheets.

- Cost Versions: Cost versions enable users to define how costing is controlled. Once a number of cost versions are created, you can make and record changes without developing new costing variants.

- Cost Tables: Special cost accounting functions in ERP software solutions should facilitate the creation of cost tables, which are very useful in analyzing cost distribution and allocation.

- Accrual Schemes: Accrual schemes are critical components of financial systems, enabling businesspeople to recognize economic events and measure the financial performance of their enterprises regardless of when cash transactions occur. Combining current with expected future cash flows, accrual schemes provide an accurate picture of an organization’s financial condition.

- Budget Models: By creating alternative budget models, such as rolling budget, incremental budget, flexible budget, zero-based budget and static budget, you can match the actual future financial performance of your business to an ideal scenario, which incorporates the best estimates of cash flows, asset replacements and sales.

Coming down to AX 2012, it’s very important to know that a series of settings influence how costs are managed. For accurate results, particular production components, including the operations, labor and resources required to produce a given product, must be considered when managing costs.

Dynamics AX 2012 R3: Intercompany Cost Accounting

Although the current version of Dynamics AX software delivers a flexible cost accounting module, the upcoming version, R3, promises enhanced accounting functionality. Besides budget allocation based on demand forecasting and changing market conditions, the new version will make possible a variety of financial scenarios, allowing subsidiaries not only to invoice each other for time, employee expenses and vendor expenses, but also to measure profitability by aligning individual revenue to the overall company turnover.