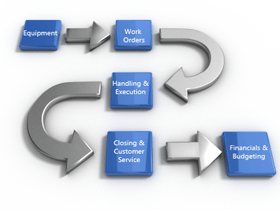

Whether the production jobs you perform are simple or complex, an integrated job cost accounting software solution can help you manage them with eas e. This solution enables you to combine work order management with certain accounting modules in order to set up new jobs, keep track of various and specific production processes, as well as the ability allocate costs to each work order separately for better cost and budget control. Since this solution gives you clear visibility into different areas of the manufacturing process, such as equipment, scheduling, labor and inventory, it assists you in solving a variety of issues in a lean and cost effective manner.

e. This solution enables you to combine work order management with certain accounting modules in order to set up new jobs, keep track of various and specific production processes, as well as the ability allocate costs to each work order separately for better cost and budget control. Since this solution gives you clear visibility into different areas of the manufacturing process, such as equipment, scheduling, labor and inventory, it assists you in solving a variety of issues in a lean and cost effective manner.

Six Problems You Can Solve with Job Costing Software

Deploying a complex job costing system includes certain advantages, from which the most essential one is that you can solve particular problems, such as:

- Inability to Track Financials on Jobs: This delineates a very serious issue for a manufacturer. Fortunately, job costing software supports multiple costing functions. One of these functions emphasizes the costs associated with each work order implied in the production process, including those related to overhead, labor, equipment, materials, sub-contractors, and miscellaneous expenses. By simply tracking all these costs, you can spot the problems that undermine the effectiveness of the manufacturing process and keep your projects in budget.

- High Inventory Costs: A minimum of 20 percent inventory reduction can be easily achieved with job cost accounting software. This reduction presents a "native" tendency to become a recurrent element that lowers different inventory costs, including those associated with equipment, handling, transportation, and warehousing. This solution also plays a vital role in managing obsolete products; increasing inventory turnover ratio; and avoiding the production of unnecessary items. This means that it can easily prevent certain issues from occurring, including stock shortage and loss of customers

- Unprofitable Jobs: Many manufacturers complain that some of the jobs they perform are unprofitable. Although some of these jobs may seem lucrative, they actually imply different hidden costs that manufacturers are unable to detect without an advanced system. This is tightly related to the “Inability to Track Job Financials” problem, except that unprofitable jobs begin with the equipment, and in order to keep profitable jobs, this solution will also need to be tied into the beginning of manufacturing processes. Considering this aspect, an increasing number of manufacturers opt for job costing solutions that help them avoid the least profitable areas and pursue jobs that fit their strengths.

- Deficient Customer Service: Streamlined production and good coordination reduces lead-time and turns specific manufacturing systems into some agile mechanisms, allowing your business to satisfy the requirements of numerous customers within a short timeframe. Cost accounting software enables manufacturers to promise accurate quotes and deliverability. This ensures a better business environment that increases customer satisfaction and improves loyalty, boosting revenue and profit.

- Inadequate Products: Typically, job cost accounting software delivers a complex database that runs through your entire business, giving you the opportunity to control different stages of the production process, from the first (design) to the last one (manufacturing). A really great thing about using this system is not necessarily the fact that it interconnects design with production, but the fact that it grants you permission to perform specific changes at different levels simultaneously in order to avoid discrepancies that may result in the production of defective goods.

- Accounting and Production Errors: Having a job costing system with a common database not only speeds up specific processes, but also increases accuracy. Besides this, the system can be set up to generate automatic reports to keep the management team updated, increasing the control you have over the production process so that you can manufacture products of higher quality.

Given all these, integrating job cost accounting software into your business is by far the best thing you can do if you want to get a competent solution that tracks and monitors all costs to ensure strong financial management.