Quick Facts on Dynamics 365 and IoT

Quick Facts on Dynamics 365 and IoT

- 82% of manufacturers using IoT increased operational efficiency and improved product quality with 49 percent fewer product defects.

- 79% of manufacturing leaders already use IoT technologies to track customers, products, business premises, or supply chains.

- Without access to IoT data, technicians need a return visit either some or all of the time.

- $10.6T Cumulative GDP impact of IoT by 2030

- For manufacturers, digitizing manufacturing and business processes has resulted in a 45 percent increase in customer satisfaction.

- 89% of manufacturing leaders recognize that customer care and quality of service are driving competitive advantage today and for the foreseeable future.⁵

- Research firm IDC estimates that by 2020, 40% of all data will be machine-generated, with 20 to 50 billion devices fueling that growth.

Another exciting aspect of Dynamics 365 Azure IoT suite is that it gives the opportunity for manufacturers to connect directly with customers and break down communication barriers between salespeople and service representatives, engineers, production/warehouse workers, and delivery drivers. By collaborating across organizational boundaries, manufacturers can engage customers throughout manufacturing in a 1:1 relationship.

By using Dynamics 365, manufacturers can improve margins and increase customer loyalty by creating more customer-focused solutions, reimagining customer experiences by delivering new smart devices and machines, and creating differentiated products and services.

How Is IoT Being Utilized Currently by Manufacturers?

Microsoft implemented the IoT suite for Liebherr, a manufacturer of refrigerators who sells to customers such as pharmaceutical companies, medical labs, and food retailers that need reliable cooling technologies to ensure that their products stay at precise temperatures during storage. Liebherr developed a prototype that monitors the temperature of each refrigerator as well as the state of the compressor and the door. Liebherr uses predictive analytics for their clients and can open service tickets before critical damage alters the valuable contents of the refrigerator.

Clint Belinsky, Vice President of Global Quality at Jabil, remarked that, “Since deploying the Microsoft predictive analytics solutions, we have seen, at least, an 80 percent accuracy rate in the prediction of machine processes that will slow down or fail, contributing to a scrap and rework savings of 17 percent.”

IoT Easier for Manufacturers with Dynamics 365

Through a collaboration with Microsoft, Jabil can analyze millions of data points from machines running dozens of steps throughout the manufacturing process. Jabil can predict failures earlier in the process—for example in a thirty-two step process, at step two the sensors can alert your company to a problem rather than at step 32. The Microsoft approach makes IoT easier for manufacturers with Dynamics 365; the Azure IoT suite starts with things you already have in your organization—whether or not they are from Microsoft, then connects them with the existing infrastructure. Industry standards, like OPC-UA in the manufacturing community, offer a quick and inexpensive way to modernize legacy systems and old equipment on the plant floor to make it cloud compatible within 24 hours. The OPC Unified Architecture (UA), released in 2008, is a platform independent service-oriented architecture that integrates all the functionality of the individual OPC Classic specifications into one extensible framework. OPC-UA makes on-premises and cloud technologies interoperate.

Microsoft solutions provide powerful ways for manufacturers to enhance and redesign processes across their organization, providing role-based access and real-time visibility into manufacturing applications, including manufacturing execution systems (MES), enterprise resource planning (ERP), human resource management (HRM), and maintenance, repair, and operations. By equipping people with the data and tools they need, they can identify areas of waste, become more lean and improve cycle times for manufacturing operations, make automation processes faster and easier, maintain equipment more predictably and proactively, dynamically realign production to meet changing customer demands, and increase turn-times for inventory across the value chain.

How Are All the Data Points Processed?

Dynamics 365 alongside Cortana and Power BI receives and processes usage insights out of data collected by the IoT devices. Microsoft’s digital solutions can help manufacturers lower operating costs by predicting and addressing inefficiencies. Smart sensors with powerful new predictive analytics capabilities let manufacturers learn about production line and component behavior, predict future outcomes, and fix problems before they become a complete outage. The business intelligence tools reduce the time and expense of analyzing large amounts of customer data with advanced cloud analytics and reduce product costs with better and faster analysis of product performance and usage.

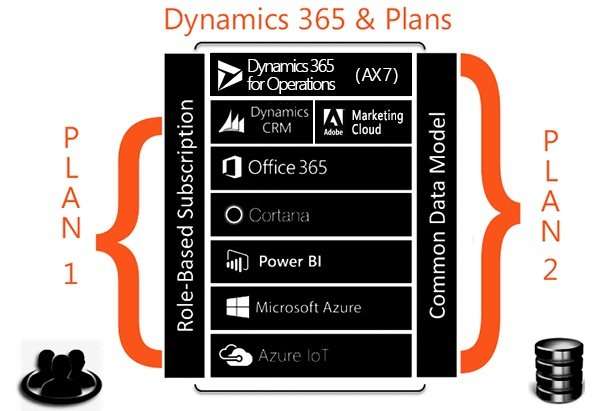

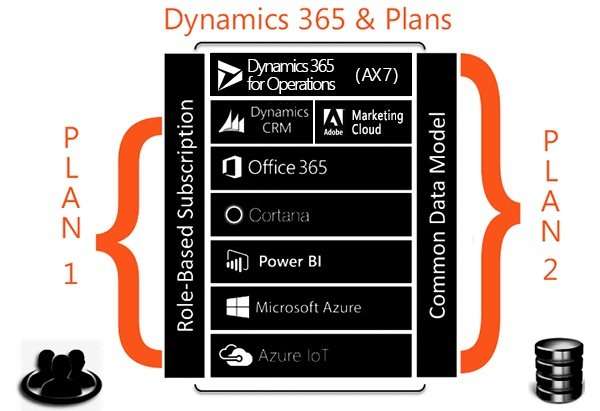

Azure IoT suite is available as a stand-alone app, or it can be purchased in Plan 1 or Plan 2 of Dynamics 365. Clients First Texas and Minnesota both implement Dynamics 365 for Operations (both a stand alone app and as a part of Dynamics 365 Plan 2). Dynamics 365 for Operations is essential for analyzing unstructured data from devices with structured data involved in the daily business processes. IoT enables your ERP system to connect people, processes, data, and connected devices in an intelligent way. This connectivity enables new business models and helps manufacturers make better decisions, as alerts will be more event-driven and intelligent. Another benefit of Microsoft is that their systems are scalable and they can process any volume of big data.

Clients First has been leveraging the power of technology since the pre-cloud days when Dynamics 365 was called Axapta in 1999. Clients First and Dynamics 365 can give your business more insight into the costs of production through the use of ERP either in the cloud or on-premise. Reach out to us at Clients First to get a demonstration of the software.

Email: Minneapolis/St. Paul, Minnesota, or call at 877.428.7205.

Email: Dallas/Fort Worth, Texas , or call at 800.331.8382.

IoT Easier for Manufacturers with Dynamics 365">

IoT Easier for Manufacturers with Dynamics 365">